06 Issues of asset management

Most businesses face this problem

01

Management of machinery and equipment (assets) craft mainly in kind. The operation and maintenance of the assessed property is based on the operator's senses and experience.

02

03

Do not automatically issue notices and warnings when the property needs repair or replacement.

04

Production assets and individual management software, independently of each other, duplicate data, limiting the ability to automate and connect business activities together.

05

Lack or no analytical data to improve performance, optimize asset operations, eliminate risk... Data is inaccurate and not real-time.

06

Investment costs and selection of capable partners to consult and implement solutions are a big challenge.

What is the current trend?

Opportunity and context

According to the State of the market said:

66% of leaders use IoT to measure risk, protect business assets, and improve employee safet

66% of leaders use IoT to measure risk, protect business assets, and improve employee safet

IDC data, manufacturing industry accounted for $102.5 billion (out of $178 billion in total IoT revenue). Thus, IoT in production, especially IoT solutions for factories, accounts for the largest proportion in the global IoT development structure.

IoT Solutions

Solution application for Asset management Smart manufacturing Performance optimization and monitoring Automated production planning Human-machine interaction Production process tracking and reporting

Management and Maintenance of production assets

Performance control and

optimization of

assets

Monitoring

and tracking from location to

monitoring parameters in several areas such as quality, performance, potential

damage or failure,

jam..

Improve equipment maintainability in a new way of predictive

maintenance.

Connecting data from departments that have direct contact with customers in Marketing, Sales with Production IoT's super-information network support planning and scheduling tools Positive changes to the production activities of enterprises.

Equipments Management and

Maintenance solution

Overview

Solutions for management and maintenance of production assets |

SmartBiz Manufacturing Asset Management and Maintenance solution integrates IoT on production assets and superior ERP platform to help digitize business processes, reduce management burden, generate sales and service better customer service.

ERP is an enterprise resource planning system , a unified, multi-functional technology application that links all activities of an enterprise, from planning, statistics, and control to providing in-depth analytical reports.

IIoT: is a Control, Monitoring, Data Collection device with a wide connection network of IoT in all production areas and factories to help businesses monitor and capture important data information in operate and maintain stable operation

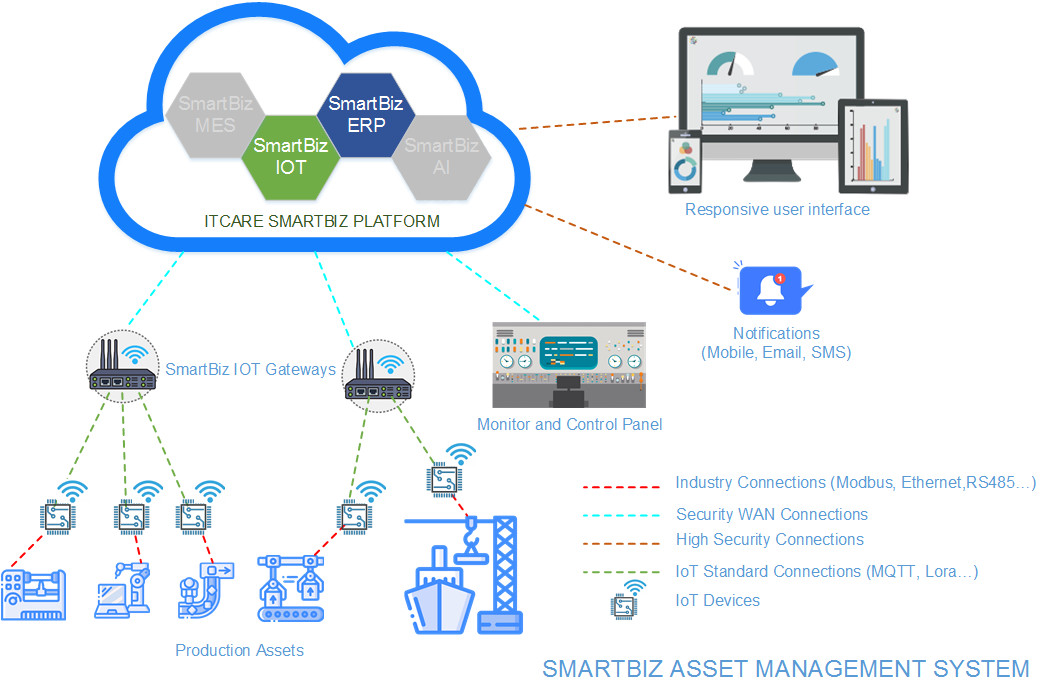

How is SmartBiz designed? |

System Platform

A comprehensive platform, designed according to each technology application, has the role of linking all activities in the enterprise.

Software platform

SmartBiz IoT: application for receiving, processing and controlling production assets.

SmartBiz ERP: a powerful business process management platform that links manufacturing operations to business operations.

SmartBiz IoT device

IoT Device: is a device that controls, monitors and collects data of a Production Asset.

IoT Gateway: acts as a gateway between IoT devices and the Internet.

User Interface: computer, tablet, Smart phone

Monitor and Control Panel: production information, assets are directly integrated with display screens arranged at production sites and ERP applications.

Product

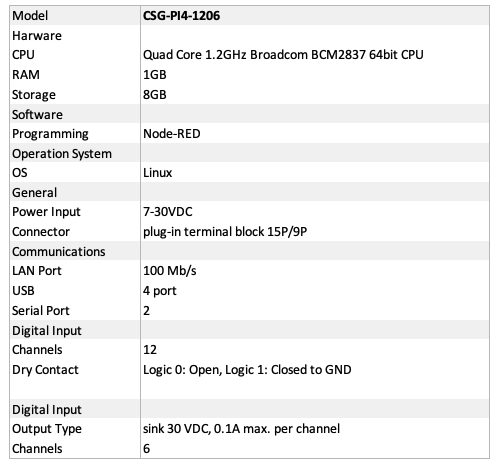

Smart Gateway- CSG series |

Specifications

|

|

|

The CSG Series is a compact smart device at the edge that provides an integrated solution based on the Linux Gateway. Monitor the operational status of Assets in real time.

Support many cloud platforms such as ICS, Azura, AWS...

Data transmission: support MQTT, Modbus, RESTful API

Control logic: Node-RED

Data acquisition: Built-in I/O port and remote I/O via RS485/Ethernet port.

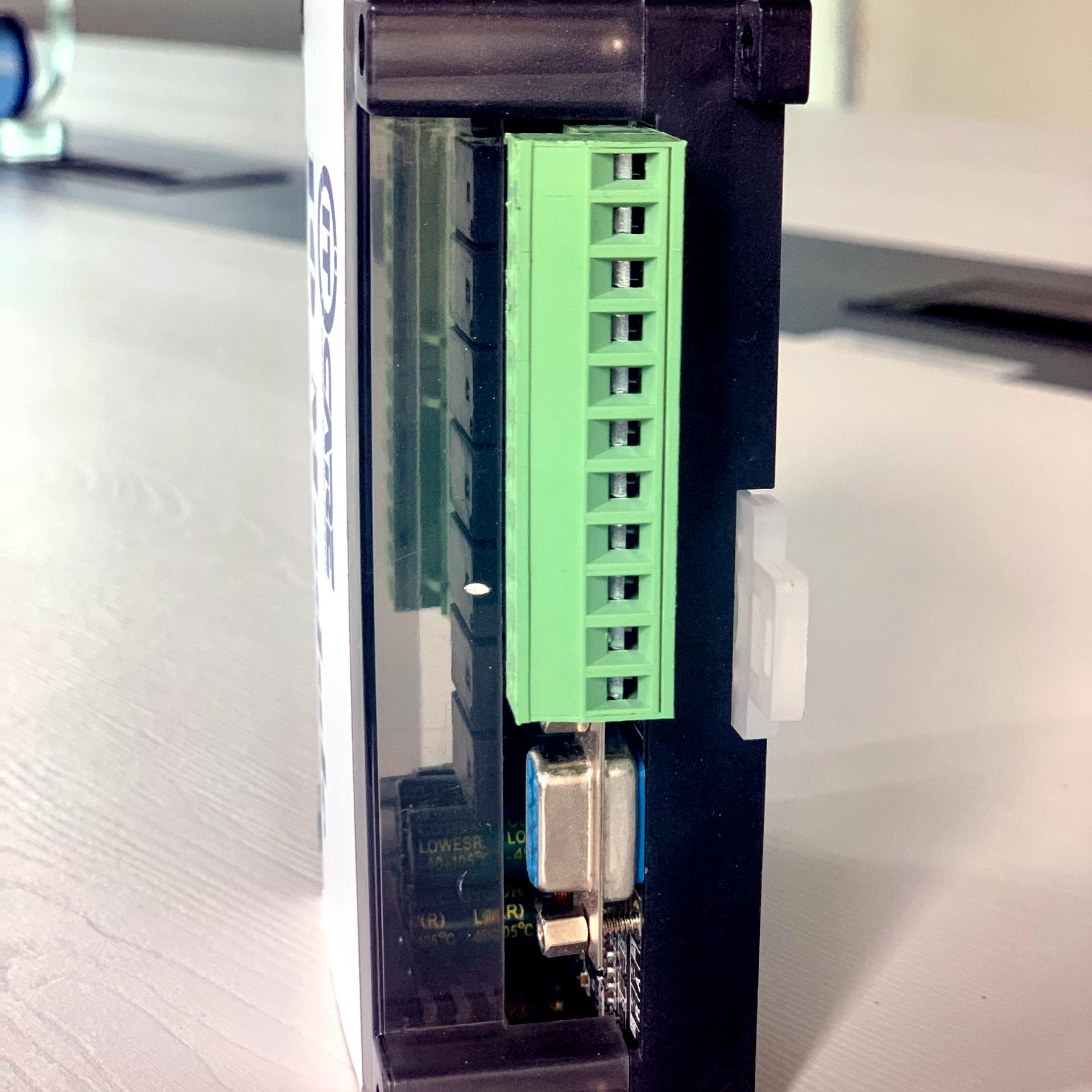

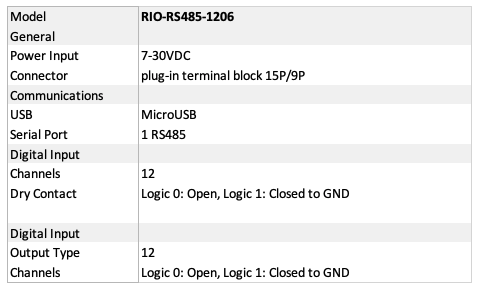

Remote I/O Modules-RIO Series |

Specifications

|

|

|

RIO Series is a device that connects directly to the Assets and transmits data to the Gateway through industry communication standards such as Ethernet, RS485, RS232..

Support digital and analog devices

Multi-connection: expand the input/output ports for factory monitoring and management system

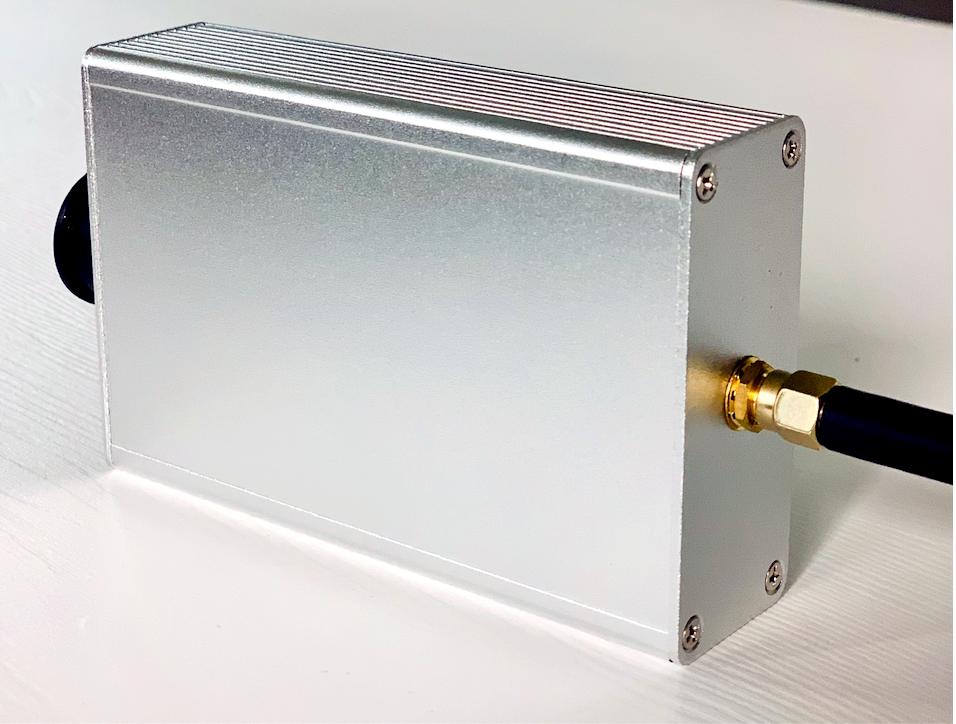

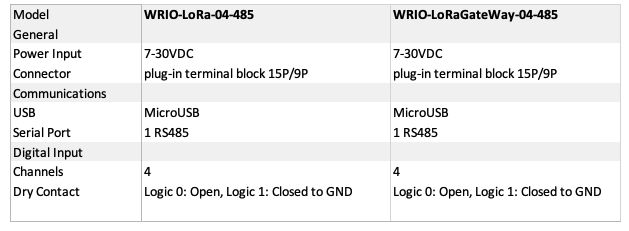

Wireless Remote I/O Modules-WRIO Series |

Specifications

|

|

WRIO Series is a device used to connect and transfer data for long distance Assets, or devices with high mobility and large range.

Support digital and analog devices

Connect LoRa/LoRaWAN, Wifi

Software

ERP Software |

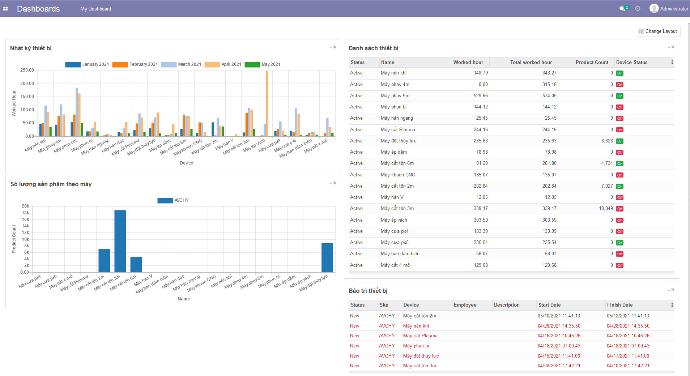

ERP software that integrates with IoT devices allows remote connection, control and control to visualize the data flow from Manufacturing Assets providing information to readers through reports.

Custom reports of indicators and parameters according to management requirements.

Multi-dimensional, automatic and real-time reporting

Asset Operations Management

Manage the list of Assets intuitively: Property code, name, year of manufacture, year of use, warranty period, design capacity, Supplier...

Provide real-time asset monitoring information: operating hours, asset status, location, capacity, consumption...

Automated data flow into the system provides immediate and proactive analysis.

Asset Maintenance Management

Issue notices and warnings when assets need repair or replacement to help business operations always be continuous or interrupted with a plan (Predictive maintenance).

Automate preventive maintenance: benchmark statistics to help you plan preventive maintenance including average time between failures, average repair time and expected next failure date . It also allows you to automatically schedule measurement and preventive maintenance.

Create great efficiency for operations

Many manual tasks are automated: automatic data collection, 24/7 automatic monitoring minimizes human involvement in some production and management stages to save labor costs. and increase data accuracy.

Applying the production execution system (MES) and making the most of real-time monitoring capabilities helps businesses track and monitor the production cycle to each location of the asset, improving accuracy. accuracy, tracking and traceability thereby limiting potential risks, incidents...

+ 1000 Customers

SIGN UP FOR A CONSULTATION/DEMO